As one of the earliest decorative materials, stone has not been widely concerned about its quality awareness and safety performance. However, with the continuous development and improvement of the stone industry and its application, especially the large number of applications of stone high-rise curtain wall, safety problems and related quality problems are becoming increasingly prominent.

The safety and quality of stone mainly involves the application of materials, stone products and construction and installation, and the safety and quality of stone products and its material performance, production process, the selection of adhesives and so on.

Nature Attributes

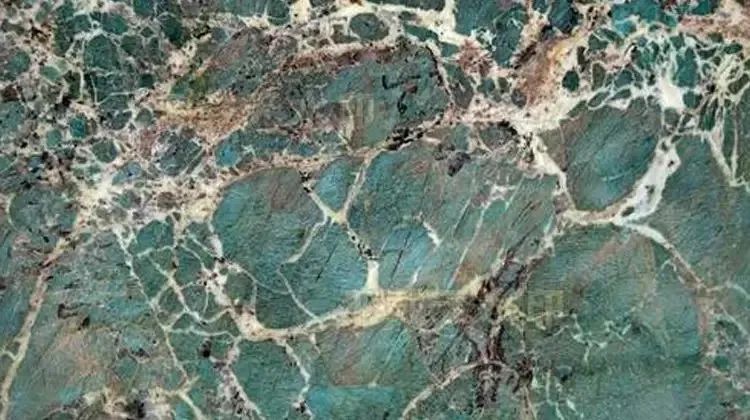

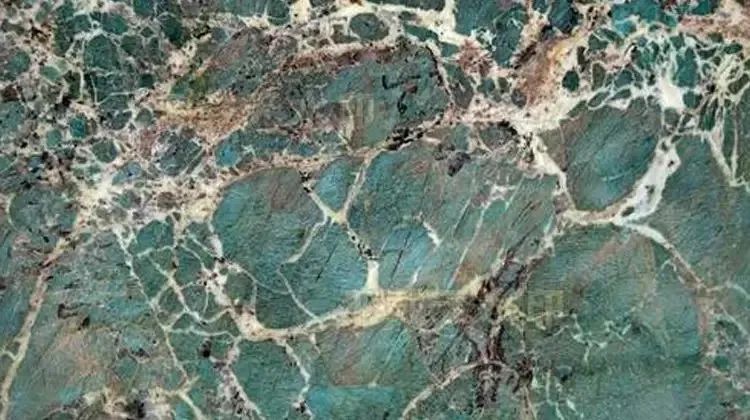

Stone is a kind of natural material, the pursuit is the integrity of natural materials, performance is very different, no two completely consistent products. Products contain a large number of cracks, hidden cracks, mud lines, suture lines and other natural defects, which can not be completely solved in the production process. Behind the beautiful stone patterns are often weak links, which are easy to break after being used and installed, causing casualties.

Natural stone products are characterized by thick, and each product can be as little as tens of kilograms or as much as hundreds of kilograms. There is a one in 10,000 chance that something will go wrong and fall down, which will cause unsafe factors for the whole building.

Physical Performance

Natural stone is divided into five categories according to the broad categories: granite, marble, limestone, sandstone and SLATE. The physical performance indicators of each category are different, and there are thousands of them according to the classification of stone varieties. The physical performance and technical indicators of each type vary greatly, even if it is the same variety. Due to the different mining site, mining level, cutting direction and technology will cause the dispersion of physical performance indicators such as volume density, water absorption, compression strength and bending strength.

These physical performance indicators are essential elements for the design and calculation of stone bearing capacity and curtain wall safety factor. If the physical performance of the actual product is lower than the design requirements, or the physical performance of some stone products is low due to natural factors, it will cause hidden risks to the stone curtain wall.

In addition, the physical properties of stone curtain wall under the natural state of temperature difference deformation, wind vibration, freeze-thaw will directly affect its safety performance.

Chemical Component

The chemical composition of all kinds of natural stones is different, rock and mineral structure is different, different use environment should choose different varieties and categories.

Granite to quartz and feldspar silicate minerals, high hardness, strength, acid and alkali resistance, suitable for all kinds of environment.

Marble, limestone and other stones mainly made of carbonate minerals are not acid resistant. They are only suitable for indoor environment, not for exterior curtain wall with acid rain environment.

-

Stone glue filling, repairing glue and surface glue processing technology

-

Marble and limestone plate processing process should be filled with glue, repair and brush surface glue to improve gloss, make up for defects, enhance physical and mechanical properties or to reach special requirements.

In this process, from the performance of adhesives to processing technology and other aspects of each link, there are usually different degrees of quality problems.

The main products are: domestic adhesive products can not reach foreign products to make the stone soft mirror luster; The transparent surface glue needed by stone such as cave stone lacks practical application. Many surface glue shrink and change color after use.

-

-

The performance of surface glue and repair glue does not conform to the characteristics of stone durability, many marble and limestone products after use, surface glue falling off, slag, fracture phenomenon, resulting in serious damage to the product appearance quality, affecting the quality of the project;

The high viscosity of the surface adhesive or the vacuum filling process is not adopted, leading to some hidden cracks are not effectively treated and the existence of defects is covered up, and the phenomenon of fracture and injury occurs in the process of handling, installation and use.

-

-

Back screen adhesive application technology

According to the characteristics of the stone, the back mesh glue is generally divided into three types:

One is that the stone defects are relatively less, taking into account the bonding problem of the stone back mesh with adhesive and cement adhesive, in the stone construction stage will be removed back mesh and glue, after brushing stone protective agent pavement construction, at this time, the back mesh glue has a short-term effect, and easy to remove;

The second is for some special stone varieties, due to shovel off the back of the net caused by stone plate fragmentation phenomenon, so the construction needs to retain the stone back net and glue, at this time the requirements of the back net glue with structural adhesive performance and good water resistance, alkali resistance;

The third is the use of dry hanging stone enhanced adhesive and back mesh, requiring sufficient bond strength and weather resistance, compatibility, in order to enhance the positive wind pressure resistance of the plate and curtain wall safety factor, to ensure the safety performance of stone curtain wall.

-

Adhesive technology

The bonding of stone products due to cracks or fracture phenomenon, as well as the bonding required by the design process (such as the combination of special-shaped stone and stone carving, etc., the reinforcement bonding of dry hanging stone, the composite bonding of stone Mosaic and ultra-thin stone composite board, etc., all need a large amount of adhesives.

In the relevant Chinese stone standards and specifications, strict use of epoxy resin adhesives and metal connectors are required on such occasions to ensure the safety of stone products.

The quality problems often occur in practice are: because the setting time of epoxy resin adhesives is too long, many enterprises use unsaturated resin adhesives for fast bonding of this kind of products, in order to achieve the purpose of robbing the construction period;

Due to the price reasons and the impact of market competition, some enterprises use fake and shoddy epoxy adhesive products for bonding, and some enterprises use a large number of additives, resulting in the decline of bond strength, aging resistance is weakened, the product performance is seriously affected;

Due to the consideration of production cost and unfamiliar with stone installation process, many stone bonding and splicing do not use metal connector bearing, only rely on the adhesive force of the adhesive hanging high in the air.

The bond strength of stone and adhesive

This kind of problem has many reasons, will lead to stone empty drum, activity, wall wet paste stone will also lead to fall off and hurt people.

The main reason is that the stone protective agent did not choose the underside type, the solvent protective agent with obvious waterproof effect was used to protect the stone, resulting in the stone underside and cement-based adhesive bond strength decline;

Cement-based adhesive is not added to the effective adhesive composition, resulting in the overall bond strength can not meet the relevant standards and specifications of the ground stone bond strength is not less than 0.5MPa, wall stone bond strength is not less than 1.0MPa;

When bonding with stone with back mesh, no reactive resin adhesive is used, or no reinforcement measures are carried out when using cement-based adhesive, such as sand bonding process; When the point adhesion method is used, the bonding area is too small; Epoxy adhesives are not used when reactive resin adhesives are used.

Diamond circular saw cutting surface granite and ordinary cement mortar bond strength is generally 0.1MPa, rough surface granite and ordinary cement mortar bond strength can be improved to about 0.2MPa, different density and water absorption of stone varieties bond strength is slightly different, and the stone after brushing protective agent and cement mortar bond strength will generally decline.

Therefore, the wet paste ground and wall stone should strictly use the bottom type of special protective agent, the stone adhesive should be used to add the resin adhesive of the special cement based adhesive, in order to improve the bond strength, can meet the standard requirements, to ensure the safety of the wall stone project.

For poor robustness, the need for stone construction with back mesh, it is recommended to use reactive resin adhesive paste; If the use of cement-based adhesive paste, need to use epoxy adhesive paste a layer of sand on the back mesh glue, and sand half exposed outside;

When the wall is constructed with wet paste method, other anti-falling measures should also be considered to ensure safety. In actual engineering, using the point adhesion method and the bonding area is too small or without the use of epoxy resin adhesive, easy to cause the wall stone falling off, the ground stone hollow drum and other problems, stone in use for a period of time will usually fall off the accident.