Steps are a common, common product in buildings. In order to increase the three-dimensional feeling of the step, the step is often thickened. However, some treads do not pay attention to the design details, so that after a period of installation, the thickened edges of the treads break or fall off, which not only affects the decorative quality of the treads, but also increases the safety hazards of the treads.

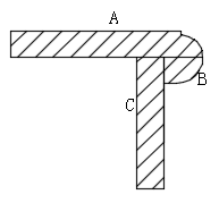

Figure 1 shows the steps taken by the author outside the lobby of a hotel. From Figure 1, it can be seen that the thickened edges of the four-layer tread have all fallen off, which is extremely ugly.

(FIG.1)

(FIG.2)

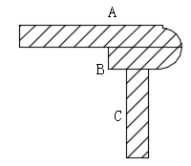

Figure 2 is an enlarged picture of Figure 1. It can be seen from the enlarged picture that there are serious problems in the design of this kind of step. The thickened edge is suspended and bonded, and the vertical plate under the step does not support the welt edge. FIG. 3 is a CAD drawing of the step structure drawn according to the step of FIG. 1 .

Add the welt as shown in Figure 3. It will not take long for the welt to break or fall off, because the welt is hanging in the air, and the granite is pasted with marble glue (should be glued with dry hanging glue), the pasting is not firm at all, and the time is slightly longer. point, it must fall off.

(FIG.3)

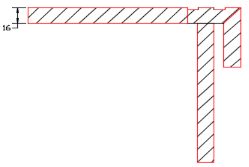

Figure 4 is more unreasonable than Figure 1, and the tread plate bonded with the 45-angle skimming bottom is more likely to break and fall off, and the thickness of the plate is very thin from Figure 4, and is estimated to be less than 16mm. The welt is not only not supported by the vertical plate, but also hangs on the outside of the vertical plate. When pedestrians step on it a little, it will be separated from the panel and fall off. FIG. 5 is a CAD drawing of the step structure drawn according to FIG. 4 .

It is not difficult to see from Figure 5 that there are serious problems with this design:

First, how can the outdoor steps of shopping malls be processed with 16mm marble?

Second, from the step that fell off in Figure 4, the tread plate is made up of two parts, as shown in Figure 5. This structure is undoubtedly easy to fall off from the splicing.

The third is the hanging structure with welt, without any support, this kind of structure, the veneer is very easy to fall off.

Fourth, the structure shown in Figure 5 is bonded with a 45-angle skimming bottom. It is difficult to apply external force during bonding to increase the bonding force, and the bonding strength is much worse than that of the flat bonding method.

(FIG.4)

(FIG.5)

Some steps I saw elsewhere are shown in Figure 6. The designer of the steps in Figure 6 designed the welt to be supported by a vertical plate. Figure 7 is the CAD drawing of the structure in Figure 6. In this way, the author did not see a piece of the welt break or fall off at the scene. This shows that the design is reasonable, the affixed edge is supported by the upward external force, which enhances the strength of the affixed edge, and the affixed edge is not easy to break and fall off.

Fig. 8 is the scene of the shopping mall decorated with the step board of the structure shown in Fig. 6. It can be seen from Fig. 8 that the step with the structure of Fig. 6 is broken and shed less frequently, and there is almost no breakage or shedding.

(FIG.6)

(FIG.7)

(FIG.8)

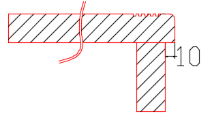

The step designer in Fig. 9 did not design to add welts. Considering that the protruding edge is easy to break and damage, the designer designed the distance of the protruding edge to be very small, about 10mm. Fig. 10 shows the step structure of Fig. 9. CAD drawings.

It can be seen from FIG. 9 that the protruding edges are hardly broken or damaged. This is a small detail to consider when designing the tread.

(FIG.9)

(FIG.10)

Figure 11 shows the stone treads at the entrances and exits of Shenzhen subway stations; Figure 12 shows the treads of the indoor stairs of Shenzhen Metro. It can be seen from these two pictures that the stepping structure is shown in Figure 10. This structure can ensure the safety of stepping in subway stations with high traffic flow, thereby ensuring the safety of pedestrians.

In a subway station with high traffic flow, if the design structure of the steps is unreasonable, if pedestrians step on the treads and step on the treads or fall off the welt, serious safety accidents are likely to occur. Places with high traffic such as subways, shopping malls, cinemas, and railway stations should never use suspended treads.

(FIG.11)

(FIG.12)

Figure 13 is a step taken at the sales office of Shenzhen Banshan No. 5 Garden, which is made of granite with a thickness of 40mm. From the perspective of safety and decorative effect, it is best to use granite of no less than 30mm for processing, and it is not recommended to make thick edges. If it is really necessary to thicken the edge, the step structure design should be considered carefully and comprehensively.

It is necessary not only to ensure the decorative effect, but also not to neglect the small details, to ensure that the steps do not break, and the welts do not fall off during use, so as to ensure the safety of pedestrians.

(FIG.13)

Treads are an indispensable product for floor and stair decoration. Attention must be paid to details in design and processing. Small details in design and processing are neglected. The processed treads will inevitably have problems in use, and may even be serious problems. cautious!

Hi! Click one of our member below to chat on